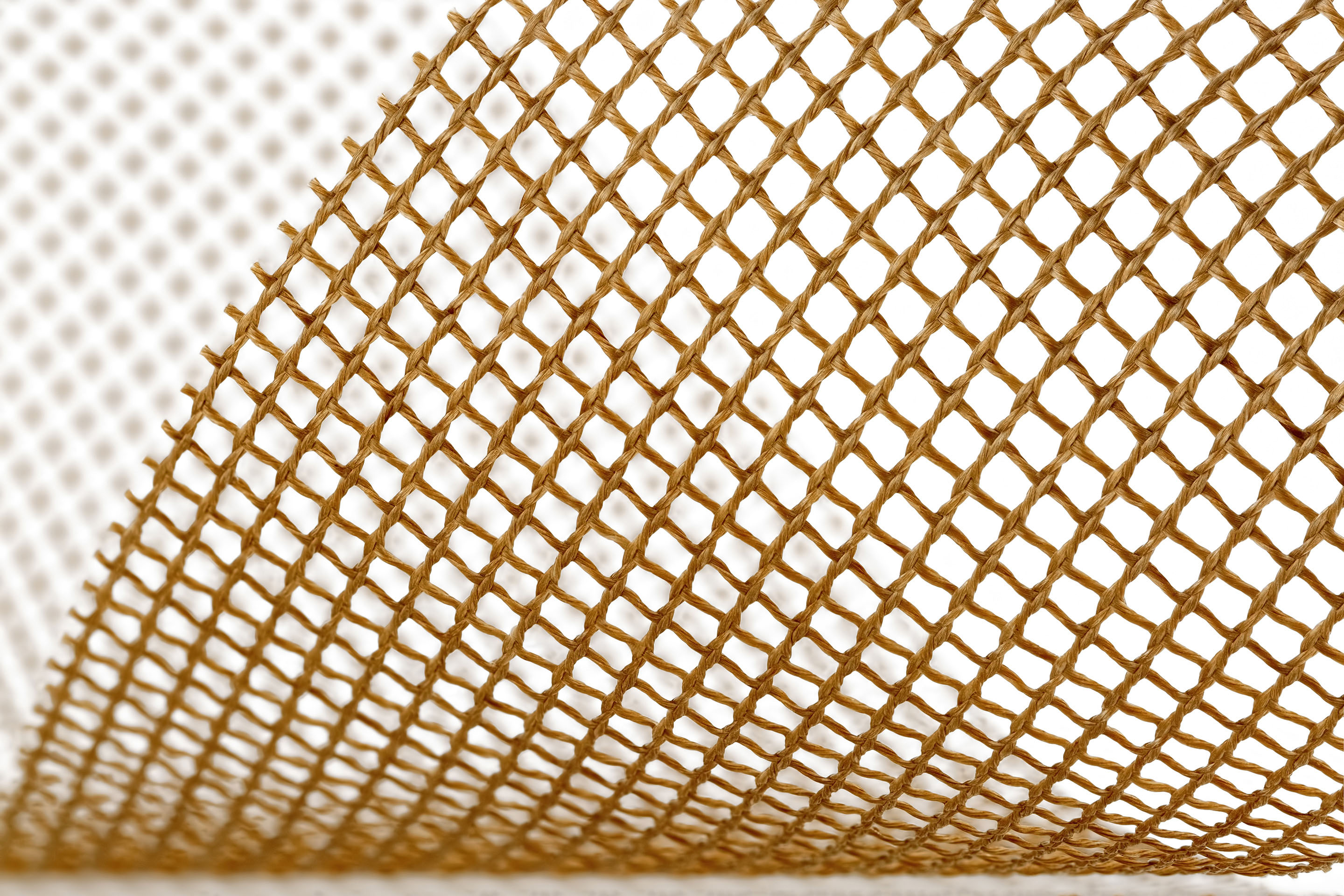

PTFE COATED KEVLAR FABRIC

DESCRIPTION

This product consists of a Kevlar fabric support coated with PTFE (polytetrafluoroethylene). The coating is perfectly even.

This is excellent for applications involving severe mechanical stress. Thanks to the combination of PTFE and Kevlar, you can enjoy enhanced productivity, an extended life span and reduced operating costs. Applications may include: food freezing, plywood and chipboard, conveyor belts for industrial processing.

PROPERTIES

Non-stick – very good slide coefficient

Resists temperatures of -73°C to +260°C over time, and peaks of up to +315°C.

Odourless and tasteless. Suitable for food contact

Chemically inert, PTFE is resistant to all chemical products including acids, salts and solvents, with the exception of fluorides (CaF2) and tri-fluorides at high temperatures and pressures, molten sodium (Na) and potassium (K) and any products which can react with glass.

Arc resistance of more than 300 seconds.

Loss factor below 2 10-4 at 60Hz, 1Hz, 106Hz

Dielectric constancy 2.1 at 60Hz, 1Hz, 106Hz

Table of the various thicknesses

| Ref: | Standard widths (mm) |

Nominal thickness (mm) |

Weight (g / m²) |

PTFE content (%) |

Tensiles (N / 5 cm) |

| 120K | 1250 | 0.13 | 185 | 49 | 1500 |

| 120GG graphite | 1250.1480 | 0.13 | 185 | 49 | 1500 |

| 235AA | 1600.2200 | 0.43 | 680 | 58 | 2200 |

| 235GG graphite | 1600.2200 | 0.43 | 680 | 58 | 2200 |

These products are used to manufacture your conveyor belts, but it is also available per m² or cut into 30m rolls at the width of your choice.